The Ultimate Guide to Fiber Optic Cables: 3 Important Types You Must Know

Kickstarting Your Journey into the World of Fiber Optics

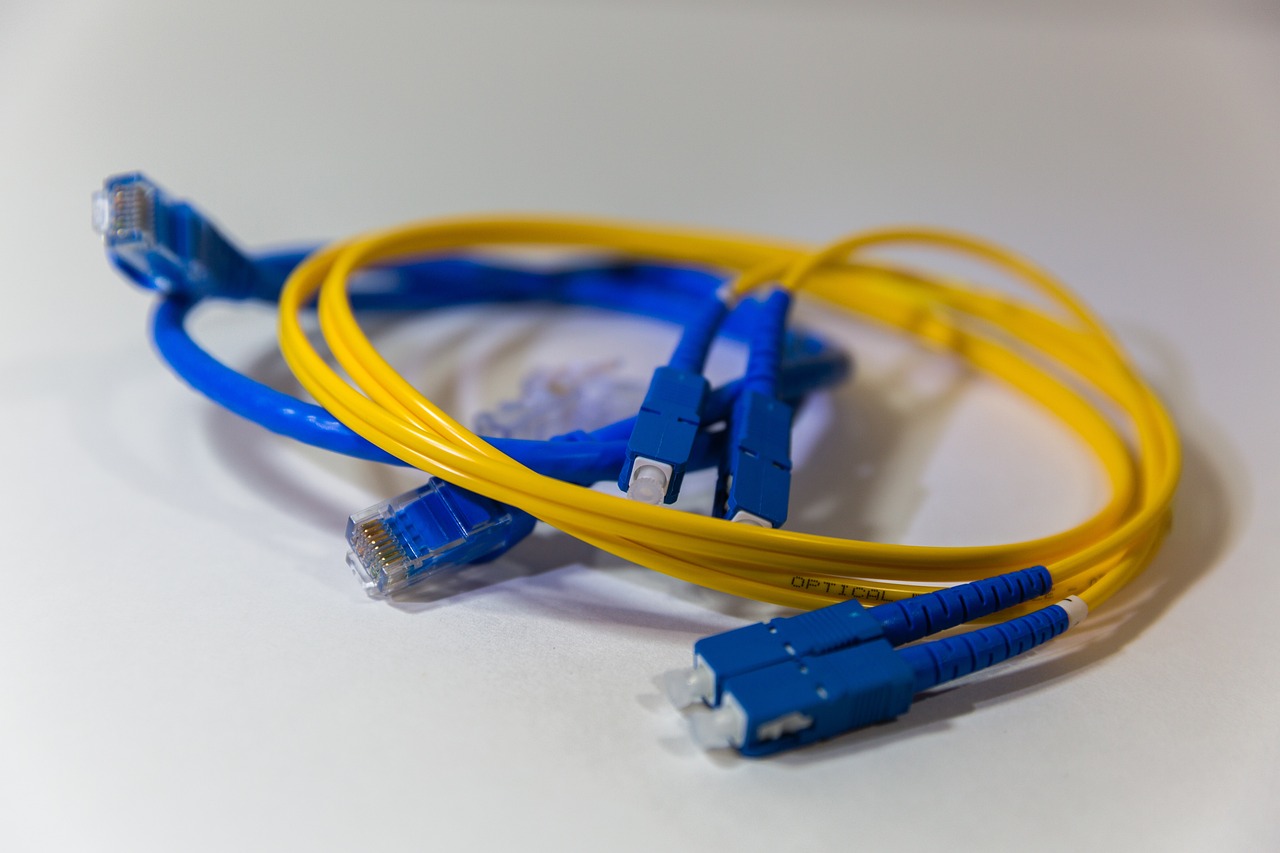

Welcome to the ultimate guide to Fiber Optic Cables! Whether you're a tech enthusiast, a student, or simply curious about the world of telecommunications, this comprehensive guide will provide you with valuable insights into the fascinating realm of fiber optic cables.

Why Fiber Optic Cables Matter

When it comes to modern connectivity and communication, fiber optic cables are at the forefront. Their significance lies in the unparalleled advantages they offer. Firstly, their speed and efficiency advantage is unmatched, enabling data to travel at incredible speeds over long distances. Secondly, these cables are crucial for future-proofing our world, as they form the backbone of advanced networks that can support evolving technologies.

Breaking Down the Basics

Understanding how fiber optic cables work is fundamental to appreciating their impact on our daily lives. These cables utilize pulses of light to transmit data, revolutionizing the way information is transferred across vast distances. From powering internet connections to facilitating international calls, their role in our daily lives is profound.

Understanding the Basics: Single Mode Fiber Optic Cables

Now, let's delve into the essence of Single Mode Fiber Optic Cables and explore their core structure, function, ideal use cases, and benefits.

The Essence of Single Mode Fiber Optic Cables

Core Structure and Function

Single Mode Fiber Optic Cables are designed with a much smaller core as compared to multimode cables. The core, typically 8-10 microns in diameter, allows only one mode of light to propagate. This focused transmission of light enables these cables to carry signals over longer distances with minimal signal loss. The precision in design and construction ensures that the light travels directly down the center of the core without bouncing off the edges, resulting in high-speed data transmission.

Ideal Use Cases and Benefits

These cables are ideally suited for long-distance communication and high-bandwidth applications. Their ability to maintain signal integrity over extended distances makes them indispensable for telecommunications networks, internet infrastructure, and long-haul networking. Additionally, single mode fiber optic cables offer higher bandwidth capacity, making them perfect for transmitting data across vast geographical areas without compromising on speed or quality.

Key Considerations for Single Mode Fiber Cable Installation

Safety First: Avoiding Eye Damage

During the installation of single mode fiber optic cables, it is crucial to prioritize safety measures to avoid potential eye damage. The laser-based technology used in these cables requires careful handling to prevent accidental exposure to harmful levels of light. Installers should always use appropriate eye protection when working with these cables to mitigate any risks associated with laser beams.

Best Practices for Long-Distance Installations

When installing single mode fiber optic cables for long-distance applications, meticulous planning is essential. Factors such as cable routing, environmental conditions, and proper cable management play a critical role in ensuring optimal performance over extended distances. It is imperative to adhere to industry best practices for cable laying and termination techniques to minimize signal attenuation and guarantee reliable connectivity over vast networks.

Diving Deeper: Multimode Fiber Optic Cables

Now, let's explore the fascinating world of Multimode Fiber Optic Cables and gain a deeper understanding of their unique characteristics and installation considerations.

Getting to Know Multimode Fiber Optic Cables

Understanding the Core Differences

When comparing multimode fiber optic cables to their single mode counterparts, it's essential to recognize the core differences that set them apart. Unlike single mode cables, which have a smaller core size, multimode cables feature a larger core diameter, typically around 50-100 microns. This larger core allows multiple modes of light to propagate, leading to a higher dispersion of signals over short distances. The broader core size makes multimode cables more cost-effective for shorter reach applications within buildings and campuses.

When to Choose Multimode Over Single Mode

The decision to choose multimode fiber optic cables over single mode depends on the specific requirements of the intended application. Multimode cables are well-suited for short-distance transmissions within localized areas such as office buildings, data centers, and campus networks. Their ability to accommodate multiple light modes makes them an ideal choice for scenarios where high bandwidth is required over relatively limited distances. Additionally, the cost-effectiveness of multimode cables makes them a practical choice for applications that do not demand extensive reach capabilities.

Navigating Multimode Fiber Cable Installation

Installation Tips for Short-Distance Applications

When installing multimode fiber optic cables for short-distance applications, it's crucial to consider factors such as connector types, cable management, and environmental conditions. Utilizing connectors that align precisely with the cable cores is essential for minimizing signal loss and ensuring reliable connectivity over short spans. Proper cable management techniques should be employed to prevent signal degradation due to bending or twisting of the cables. Additionally, assessing environmental factors like temperature and humidity can contribute to optimizing performance in short-distance installations.

Maximizing Performance in Data Centers

Data centers represent critical environments where the performance of fiber optic cabling plays a pivotal role in maintaining seamless operations. In these settings, maximizing the performance of multimode fiber optic cables involves meticulous planning and adherence to industry best practices. Employing advanced termination methods and utilizing high-quality connectors are essential steps in ensuring optimal signal integrity within data center infrastructures. Furthermore, implementing effective cable routing strategies and regular maintenance routines can significantly enhance the overall performance and reliability of multimode fiber optic systems in data center environments.

Exploring the World of Plastic Optical Fiber (POF)

As we venture further into the realm of Plastic Optical Fiber (POF), we uncover a fascinating alternative to traditional fiber optic cables that offers unique properties and practical applications.

An Introduction to Plastic Optical Fiber (POF)

The Basics of POF and Its Unique Properties

Plastic Optical Fiber, as the name suggests, is composed of optical-grade polymers such as polymethylmethacrylate (PMMA) or polycarbonate. Unlike glass-based fiber optics, POF boasts a larger core diameter, typically around 0.5 to 1 millimeter. This characteristic makes POF more flexible and easier to handle during installation, catering to scenarios where tight bends or rugged environments are prevalent. Additionally, the use of plastic materials renders POF more cost-effective than traditional fiber optic cables, making it an attractive option for specific applications.

Comparing POF to Traditional Fiber Optic Cables

When comparing POF to traditional fiber optic cables, several distinct differences emerge. While traditional fiber optics excel in long-distance transmissions and high-bandwidth applications, POF shines in short-range communications within confined spaces. The flexibility and durability of POF make it an ideal choice for home networking, automotive systems, and other localized connectivity needs. Furthermore, the ease of installation and lower susceptibility to damage from bending positions POF as a practical solution for DIY enthusiasts and beginners entering the world of fiber optics.

Practical Applications and Installation Tips for POF

Where POF Shines: Home and Automotive Uses

Plastic Optical Fiber finds its niche in various home networking applications due to its user-friendly characteristics. From creating robust networks for smart homes to establishing reliable connections for entertainment systems, Fiber Optic enthusiasts can leverage the flexibility and affordability of POF to meet their connectivity needs effectively. Moreover, in automotive settings, where space constraints and rugged conditions are prevalent, POF serves as a resilient medium for transmitting data signals within vehicles. Its ability to withstand vibrations and harsh environments makes it a preferred choice for automotive networking solutions.

DIY Installation Guide for Beginners

For individuals venturing into the world of Fiber Optic installations for the first time, working with Plastic Optical Fiber presents an accessible entry point. The larger core diameter of POF simplifies connectorization processes compared to traditional fiber optics. When embarking on a DIY installation project with POF, beginners should prioritize proper handling techniques to avoid micro-bends or kinks that could impact signal integrity. Utilizing specialized tools designed for working with plastic fibers ensures precision during cutting and termination processes. Additionally, maintaining gentle curves rather than sharp bends when routing POF cables contributes to preserving signal quality over short distances.

Practical Tips for Fiber Cable Installation

Now that you're ready to embark on your fiber optic cable installation journey, it's essential to prepare meticulously and follow a systematic approach to ensure a successful and seamless process.

Preparing for Your Fiber Optic Cable Installation

Tools and Materials Checklist

Before initiating the fiber cable installation, it's crucial to gather the necessary tools and materials to facilitate the process. Here's a checklist of items you'll need:

Fiber optic cables: Ensure you have the appropriate type of fiber optic cables based on your specific requirements, whether it's single mode or multimode.

Cable connectors: Select connectors compatible with your chosen fiber optic cables for secure terminations.

Splice closures: If splicing is required, have splice closures ready to protect and organize the spliced fibers.

Cable pulling grips: These aids in safely pulling the cables through conduits or ducts during installation.

Fiber cleaver: A precision tool used to make clean and accurate cuts on fiber optic cables during termination.

Power meter and light source: Essential for testing signal strength and continuity post-installation.

Planning Your Installation Route

Careful planning of the installation route is paramount to ensure optimal performance and longevity of the fiber optic network. Consider the following factors:

Pathway selection: Choose pathways that minimize bends and twists in the cables, reducing signal loss.

Environmental considerations: Assess environmental conditions such as temperature, moisture, and potential sources of interference along the installation route.

Safety measures: Identify any potential hazards or safety risks along the pathway, ensuring a safe working environment for installers.

Step-by-Step Guide to Installing Fiber Optic Cables

Laying the Cables: Dos and Don'ts

When laying out the fiber optic cables, adhere to these dos and don'ts for a successful installation:

Dos:

Do use proper cable management techniques to avoid excessive bending or tension on the cables.

Do label both ends of each cable accurately for easy identification during termination processes.

Do maintain clear documentation of cable routing paths for future reference.

Don'ts:

Don't exceed maximum pulling tensions specified by cable manufacturers to prevent damage to the fibers.

Don't mix different types of fiber optic cables within the same pathway unless explicitly designed for compatibility.

Testing for Success: Ensuring Your Installation Works

After completing the installation, thorough testing is essential to validate its success. Utilize a power meter and light source to measure signal strength at various points along the installed cables. Additionally, perform continuity tests to verify seamless connectivity throughout the network.